Trump’s 50% Steel Tariffs: Supply Chain Disruption Explained

Trump’s 50% Steel Tariffs: Industry Pushback and Supply Chain Disruption…

Trump’s 50% Steel Tariffs: Industry Pushback and Supply Chain Disruption…

Businesses approaches to supply chain management were drastically altered by…

A quick summary and overview Cross-docking transforms traditional logistics by…

Handling Hazards: How WHMIS-Compliant Logistics Protect Your Homecare Brand A…

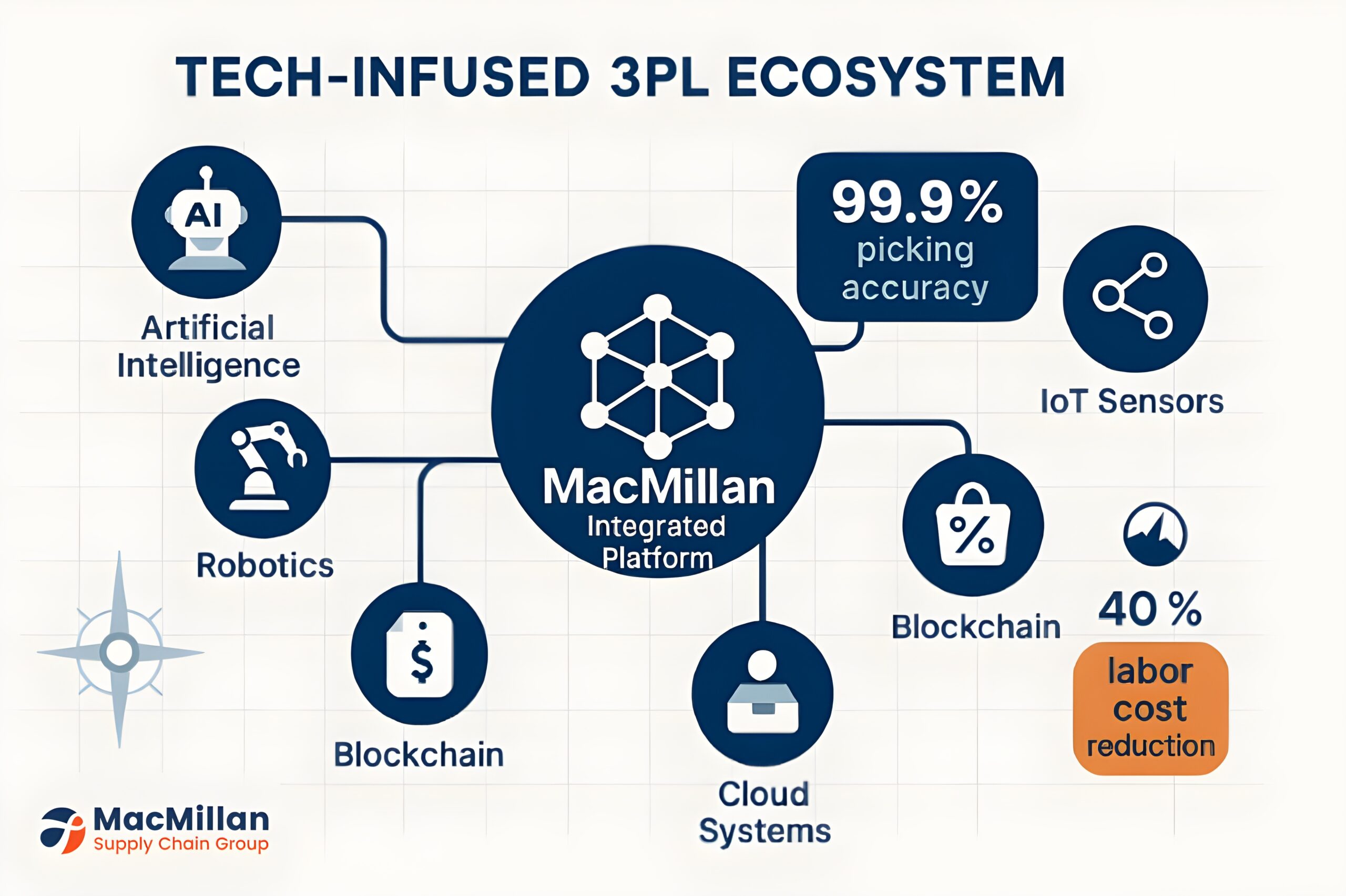

The logistics industry is experiencing a technological revolution that’s reshaping how goods move from manufacturers to consumers. Tech-infused 3PL combines artificial intelligence, robotics, IoT sensors, and advanced analytics to create smarter, faster, and more reliable supply chains. At MacMillan Supply Chain Group, we’re leading this transformation in the Canadian market, helping businesses optimize operations, reduce costs, and improve customer satisfaction through innovative logistics technology. This article explores how these technologies are changing the logistics landscape and why partnering with a tech-forward 3PL provider is essential for modern business success.

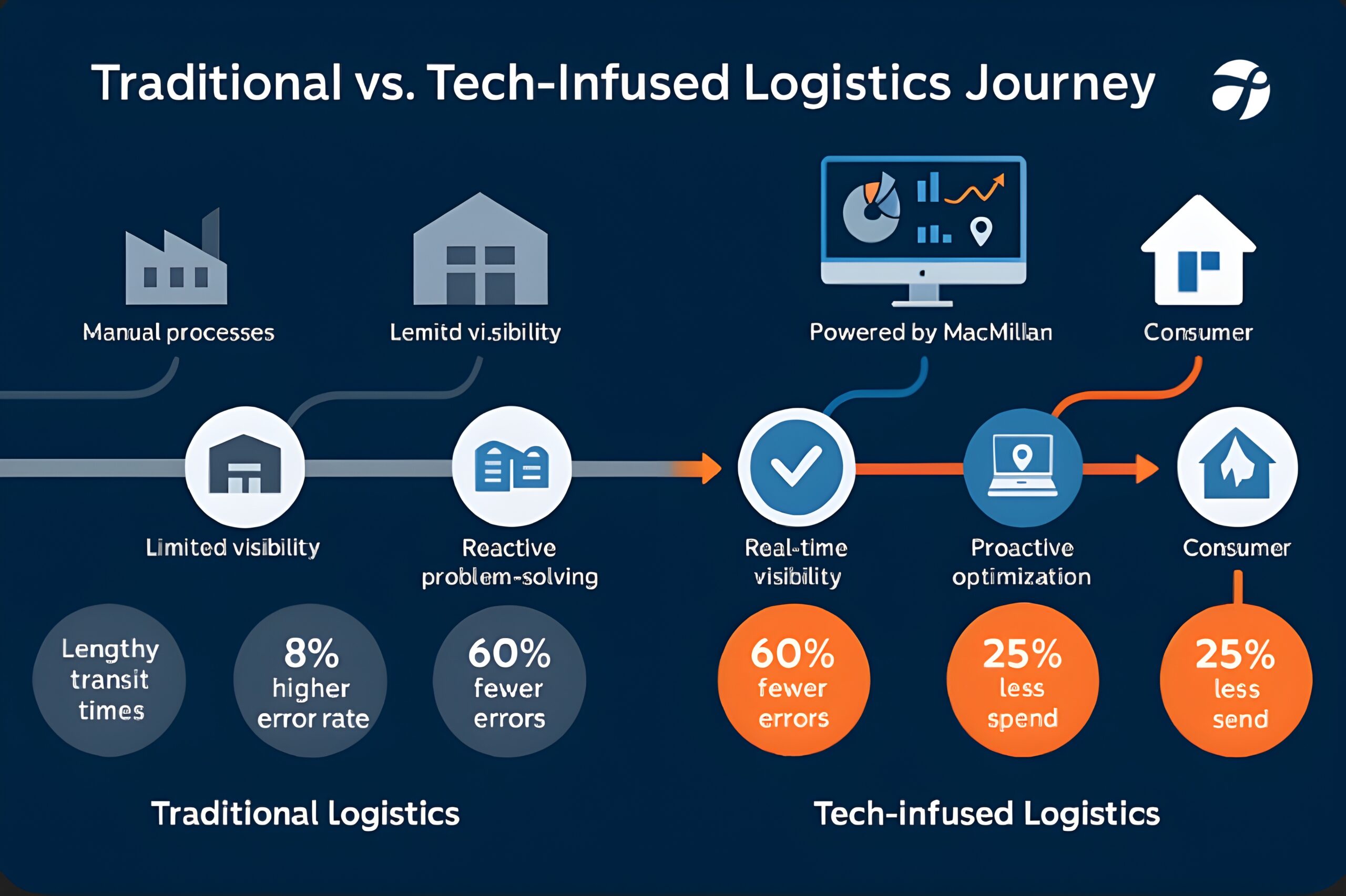

The logistics industry has come a long way from manual processes and paper trails. Today, technology is fundamentally transforming how third-party logistics (3PL) providers operate, creating unprecedented efficiency and visibility throughout the supply chain. This tech-infused approach is revolutionizing everything from warehouse operations to last-mile delivery.

In the Canadian 3PL market, where businesses face unique challenges of vast geography and variable weather conditions, technology adoption isn’t just an advantage—it’s a necessity. Digital transformation in logistics is enabling companies to overcome these challenges while meeting rising customer expectations for speed and transparency.

At MacMillan Supply Chain Group, we’ve embraced this technological revolution, implementing cutting-edge solutions that streamline operations and provide superior service. But what exactly makes a 3PL provider “tech-infused,” and how are these technologies changing the logistics landscape? Let’s explore the innovations reshaping our industry and how they benefit businesses across Canada.

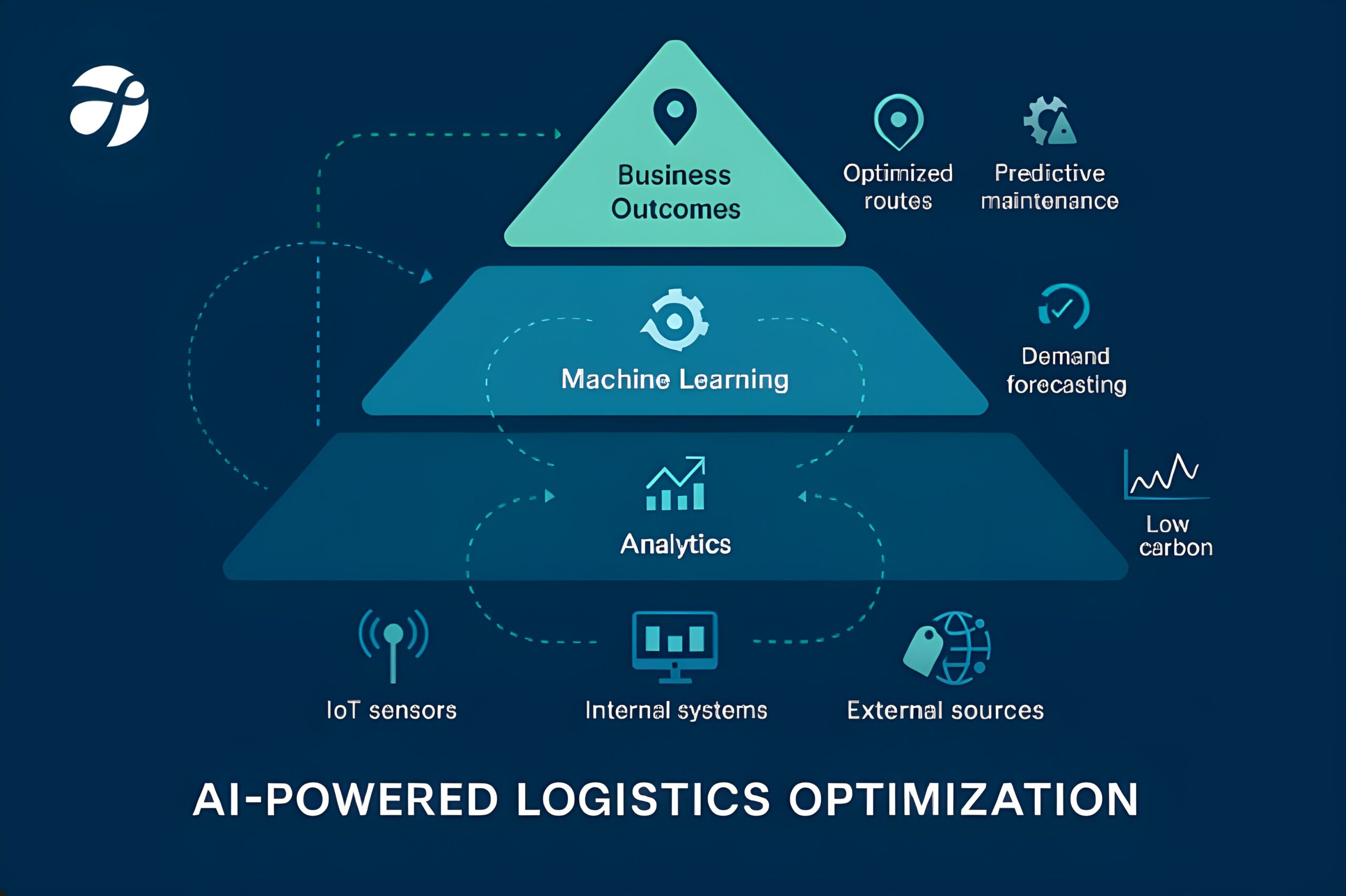

Artificial intelligence and machine learning represent the cognitive center of tech-infused 3PL operations. These technologies analyze massive datasets to identify patterns, make predictions, and optimize decisions in ways that human operators simply cannot match.

AI in supply chain management transforms raw data into actionable insights, enabling smarter inventory management and demand forecasting. For example, AI algorithms can analyze historical sales data alongside external factors like weather patterns, local events, and economic indicators to predict future demand with remarkable accuracy. This helps businesses maintain optimal inventory levels—not too much (which ties up capital) and not too little (which leads to stockouts).

Route optimization is another area where AI shines. Traditional route planning might consider basic factors like distance, but AI systems evaluate countless variables simultaneously: traffic patterns, weather conditions, delivery time windows, vehicle capacities, driver schedules, and even customer preferences. The result? Faster deliveries, lower fuel costs, and improved customer satisfaction.

At MacMillan Supply Chain Group, our AI-powered systems continuously learn from each delivery, becoming increasingly efficient over time. This machine learning capability means our logistics solutions aren’t static—they evolve and improve automatically, adapting to changing conditions and incorporating new data to deliver ever-better results for our clients.

Robotics in warehousing has revolutionized how products are stored, picked, and packed. These technologies are no longer futuristic concepts—they’re operational realities delivering measurable benefits in modern fulfillment centers.

Automated guided vehicles (AGVs) navigate warehouse floors independently, transporting goods between stations without human intervention. These tireless workers operate 24/7, dramatically increasing throughput while reducing labor costs and human error. Meanwhile, robotic picking systems can identify, grasp, and move individual items with precision that rivals or exceeds human capabilities.

Warehouse automation solutions extend beyond robots to include sophisticated conveyor systems, automated storage and retrieval systems (AS/RS), and goods-to-person technologies that bring products directly to packing stations. These integrated systems work in harmony to process orders with unprecedented speed and accuracy.

The benefits of automation are particularly evident in e-commerce logistics, where high order volumes and expectations for rapid fulfillment create intense operational pressure. Our automated facilities at MacMillan can process thousands of orders daily with 99.9% accuracy, enabling next-day and same-day delivery options that would be impossible with traditional manual processes.

The Internet of Things (IoT) has created unprecedented visibility throughout the supply chain by connecting physical objects to digital networks. This connectivity transforms static supply chains into dynamic, responsive systems that can be monitored and optimized in real time.

IoT fleet management uses connected sensors on vehicles to track location, monitor fuel consumption, assess driver behavior, and evaluate vehicle health. These systems enable proactive maintenance that prevents breakdowns, optimizes fuel efficiency, and ensures regulatory compliance. For temperature-sensitive goods like pharmaceuticals or food products, IoT sensors continuously monitor conditions, triggering alerts if temperatures drift outside acceptable ranges.

Real-time tracking solutions extend beyond vehicles to the products themselves. RFID tags, GPS trackers, and other connected devices provide item-level visibility throughout the journey from manufacturer to consumer. This granular tracking enables precise delivery estimates and proactive problem-solving when issues arise.

At MacMillan Supply Chain Group, our connected logistics network generates a continuous stream of data that feeds our analytics platforms. This real-time information allows us to make dynamic adjustments to routes, reallocate resources, and keep customers informed about their shipments’ status. The result is a more agile, responsive, and transparent supply chain that delivers superior results for our clients.

Blockchain technology is bringing unprecedented transparency and security to logistics operations. This distributed ledger system creates immutable records of transactions and events, providing a single source of truth that all supply chain participants can trust.

In shipping and logistics, blockchain creates transparent, tamper-proof records of a product’s journey from origin to destination. This capability is particularly valuable for high-value goods, pharmaceuticals, and food products where authenticity and handling conditions are critical concerns. When implemented properly, blockchain in shipping can virtually eliminate counterfeiting and provide indisputable evidence of proper handling throughout the supply chain.

Beyond product tracking, blockchain streamlines documentation processes that have traditionally been paper-heavy and time-consuming. Smart contracts—self-executing agreements with terms written directly into code—can automatically trigger payments when predefined conditions are met, such as successful delivery confirmation.

Data security is another crucial aspect of tech-infused 3PL operations. As supply chains become increasingly digital, protecting sensitive information from cyber threats becomes paramount. At MacMillan Supply Chain Group, we implement robust cybersecurity measures to safeguard our systems and our clients’ data, ensuring that the benefits of digital transformation don’t come at the cost of increased vulnerability.

Despite technological advances, many businesses still struggle with outdated logistics processes that create significant challenges:

At MacMillan Supply Chain Group, we’ve developed comprehensive solutions to address these challenges through our tech-infused 3PL approach:

Our cloud-based logistics management system serves as the central nervous system of our operations, connecting all aspects of the supply chain. This integrated platform eliminates silos by bringing together warehouse management, transportation management, order processing, and analytics in a single, unified system. Clients gain access to customizable dashboards that provide real-time visibility into their operations, enabling data-driven decisions and proactive management.

The platform’s open architecture facilitates seamless integration with client systems through standardized APIs, eliminating double data entry and ensuring information flows smoothly between systems. This integration capability extends to e-commerce platforms, ERP systems, and marketplace channels, creating a truly connected ecosystem.

Our artificial intelligence systems continuously analyze operational data to identify patterns, predict outcomes, and recommend improvements. These capabilities transform every aspect of logistics management:

Demand forecasting: Our predictive models analyze historical data alongside market trends, seasonal factors, and promotional activities to forecast demand with remarkable accuracy, helping clients maintain optimal inventory levels.

Intelligent routing: AI algorithms consider multiple variables simultaneously—traffic patterns, weather conditions, delivery windows, vehicle capacities—to create optimized delivery routes that minimize costs while meeting service commitments.

Exception management: The system automatically identifies potential disruptions and suggests mitigation strategies before problems impact customers, turning potential crises into manageable situations.

Our fulfillment centers leverage cutting-edge automation technologies to maximize efficiency and accuracy:

Our transportation operations leverage IoT technology to create a responsive, efficient delivery network:

Our implementation of blockchain technology creates unprecedented supply chain transparency:

Transitioning to a tech-infused logistics approach doesn’t have to be overwhelming. Here’s how businesses can successfully implement these solutions:

For businesses looking to accelerate their logistics transformation, partnering with MacMillan Supply Chain Group offers a faster path to results. Our team brings decades of logistics expertise combined with cutting-edge technology capabilities, allowing you to leverage our investments and experience rather than building everything from scratch.

Contact MacMillan Supply Chain Group today to discover how our tech-infused 3PL solutions can transform your logistics operations. Our consultative approach begins with understanding your unique challenges and objectives, then designing a customized solution that delivers measurable improvements in efficiency, visibility, and customer satisfaction. Whether you’re looking to optimize a specific aspect of your supply chain or implement a comprehensive logistics transformation, we have the expertise and technology to help you succeed.

A tech-infused 3PL provider is a logistics company that leverages advanced technologies like artificial intelligence, robotics, IoT sensors, and blockchain to optimize supply chain operations. Unlike traditional 3PL providers that may rely primarily on manual processes, tech-infused providers integrate digital solutions throughout their operations. At MacMillan Supply Chain Group, our technology stack includes warehouse management systems, transportation management platforms, real-time tracking solutions, and advanced analytics tools that work together to create more efficient, transparent, and reliable logistics operations.

AI improves logistics operations in numerous ways. It analyzes historical data and market trends to forecast demand more accurately, helping businesses maintain optimal inventory levels. AI-powered route optimization considers multiple variables simultaneously—traffic patterns, weather conditions, delivery windows, vehicle capacities—to create more efficient delivery routes. Machine learning algorithms continuously analyze operational data to identify inefficiencies and recommend improvements. At MacMillan, our AI systems even predict potential disruptions before they occur, allowing for proactive problem-solving that prevents delays and service failures.

Warehouse automation delivers multiple benefits including increased processing speed (typically 2-3x faster than manual operations), improved accuracy (99.9%+ compared to 96-98% for manual picking), reduced labor costs (30-50% savings in many operations), better space utilization (15-25% improvement through more efficient storage systems), and enhanced scalability to handle volume fluctuations without proportional staffing increases. These improvements translate to faster order fulfillment, fewer errors, lower operational costs, and the ability to reliably meet customer expectations even during peak periods.

Real-time tracking improves customer satisfaction by providing transparency throughout the delivery process. Customers can see exactly where their orders are and when they'll arrive, eliminating uncertainty and reducing anxiety. When delays occur, proactive notifications set appropriate expectations and demonstrate respect for customers' time. For businesses, real-time tracking enables proactive customer service—addressing potential issues before customers need to inquire about them. At MacMillan Supply Chain Group, our tracking systems integrate with customer communication platforms to provide automated updates at key milestones, enhancing the customer experience while reducing service inquiries.

While not every logistics operation requires blockchain, the technology offers significant benefits for certain applications. Blockchain is particularly valuable for high-value goods, pharmaceuticals, food products, and international shipments where authenticity, handling conditions, and chain of custody are critical concerns. It creates immutable records that prevent fraud, simplifies documentation processes, and provides indisputable evidence of compliance with regulatory requirements. For businesses dealing with complex supply chains, multiple handoffs, or stringent compliance requirements, blockchain can deliver substantial value by increasing transparency and reducing administrative burden.

Small and medium-sized businesses can access tech-infused logistics through partnerships with providers like MacMillan Supply Chain Group. By working with a tech-forward 3PL, businesses leverage shared infrastructure and expertise without making substantial upfront investments. Our scalable pricing models align costs with usage, making advanced logistics technology accessible even for smaller operations. Additionally, many technologies deliver rapid ROI through operational savings, reduced errors, and improved customer satisfaction, making them financially viable even for businesses with limited resources.

Common implementation challenges include integration with existing systems, employee adoption, data quality issues, and process redesign requirements. At MacMillan Supply Chain Group, we address these challenges through comprehensive implementation planning, phased approaches that minimize disruption, thorough training programs, and ongoing support. Our experience with numerous technology implementations helps us anticipate potential issues and develop effective mitigation strategies, ensuring smooth transitions and positive outcomes.

Tech-infused 3PL supports sustainability through multiple mechanisms. Route optimization reduces fuel consumption and emissions by minimizing distance traveled and avoiding congestion. Warehouse automation decreases energy usage through more efficient operations and reduced space requirements. Predictive analytics enables more accurate inventory management, reducing waste from obsolete products. At MacMillan Supply Chain Group, we also leverage technology to measure environmental impact, providing clients with detailed carbon footprint reporting and recommendations for further sustainability improvements.

In a tech-infused logistics environment, multiple security measures protect sensitive data. These include encryption for data both in transit and at rest, multi-factor authentication for system access, regular security audits and penetration testing, comprehensive backup systems, and strict access controls based on role-based permissions. At MacMillan Supply Chain Group, we maintain SOC 2 compliance and implement industry-leading security practices to safeguard our systems and our clients' data, ensuring that the benefits of digital transformation don't come at the cost of increased vulnerability.

Logistics technology will continue to evolve rapidly, with several key trends on the horizon. Autonomous vehicles and drones will increasingly handle transportation and delivery tasks, particularly for last-mile operations. Artificial intelligence will become more sophisticated, moving from reactive to truly predictive capabilities. Augmented reality will enhance warehouse operations through visual picking guidance and remote assistance. The Internet of Things will expand to create even more connected supply chains with granular visibility. At MacMillan Supply Chain Group, we continuously monitor these trends and strategically adopt emerging technologies that deliver meaningful benefits to our clients.