Cobots & Labor-Tech Solving Canada Warehouse Worker Shortage

The critical 11% vacancy rate in transportation and warehousing that…

The critical 11% vacancy rate in transportation and warehousing that…

Growing tariffs, geopolitical unrest, and changing manufacturing environments present the…

Trump’s 50% Steel Tariffs: Industry Pushback and Supply Chain Disruption…

Businesses approaches to supply chain management were drastically altered by…

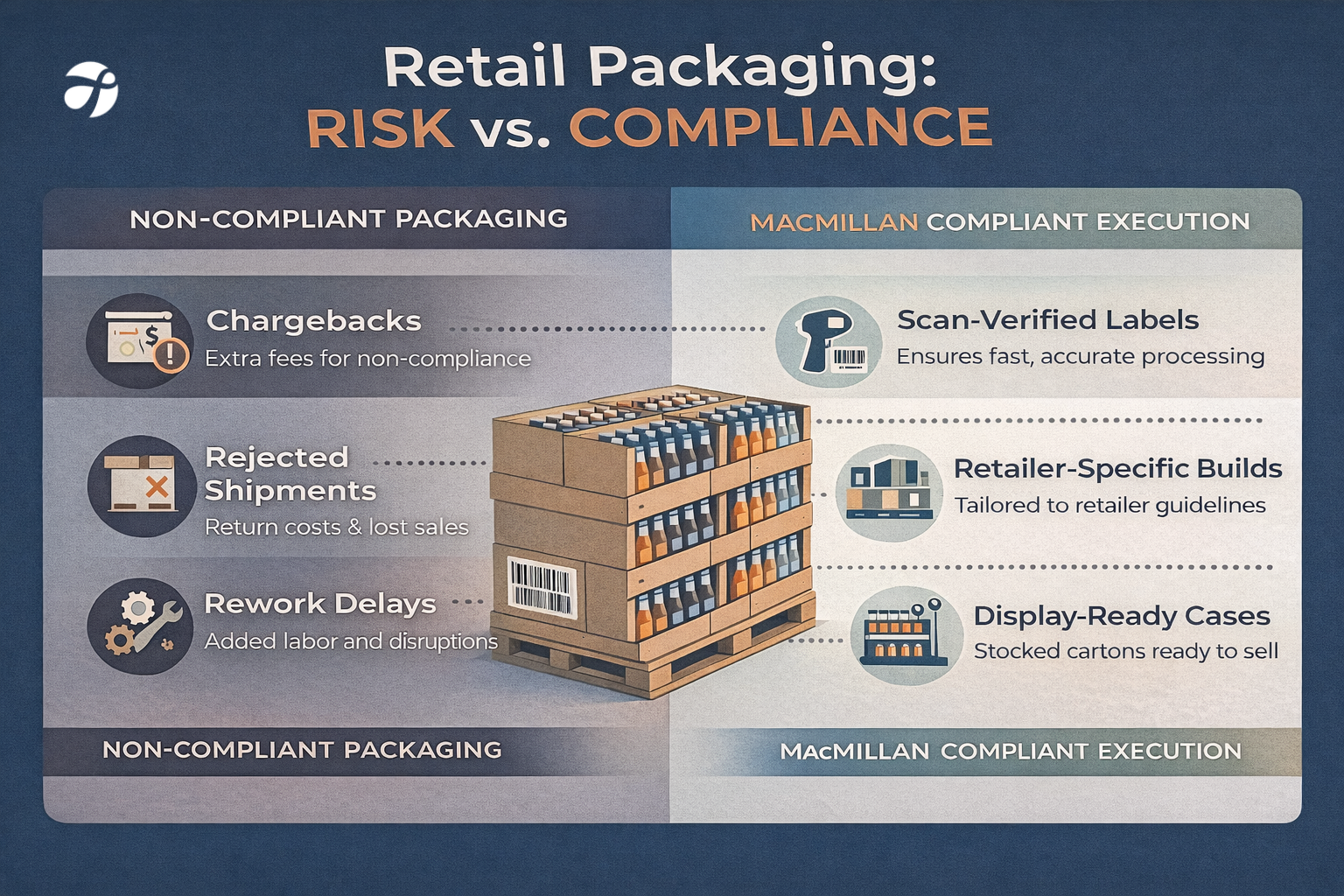

Retail-ready packaging (RRP), also known as shelf-ready packaging, is a crucial logistics component for any brand supplying large retailers. With major chains demanding faster shelf replenishment, standardized labeling, and reduced labor costs, non-compliant packaging can lead to costly chargebacks and missed sales windows. MacMillan Supply Chain Group ensures that your retail shipments are compliant, scan-verified, and shelf-ready—every time. This blog explores what retail-ready packaging is, why it matters for FMCG and CPG brands, and how MacMillan helps businesses stay compliant and competitive.

Retail-ready packaging (RRP) refers to secondary packaging designed to go straight from warehouse to retail shelf without requiring unpacking or reconfiguration. It includes features like:

Retailers like Walmart, Costco, Loblaw, and Canadian Tire all have strict RRP guidelines. These aren’t suggestions—they’re delivery requirements. Non-compliance means rejected shipments, fines, or delisting.

Brands that overlook RRP risk the following:

Seasonal and promotional products are particularly vulnerable—there are no second chances.

MacMillan SCG specializes in retail-ready logistics. Here’s how we help:

Whether you’re shipping to national grocery chains or big box retailers, we ensure your packaging meets every standard.

Different product types demand different packaging execution. MacMillan adapts RRP workflows based on your category:

Our category specialization ensures your product doesn’t just arrive—it sells.

Well-executed RRP not only avoids penalties, it accelerates sell-through and strengthens retailer relationships:

At MacMillan, we see packaging not just as a box—but a brand ambassador.

MacMillan Supply Chain Group delivers retail-ready packaging that’s more than compliant—it’s competitive.

Talk to us about aligning your packaging workflows with top retailer requirements in Canada.

📞 Contact us for a category audit and see how we can streamline your supply chain from dock to shelf.

Retail-ready packaging is designed for easy stocking and display. It includes pre-applied barcodes, clear product visibility, and structural support for stacking. Retailers can unpack and place it on the shelf in seconds.

Non-compliant shipments may be rejected at distribution centers, delayed, or incur chargebacks. It also risks damaging retailer trust and can result in delisting over time.

We use automated scan verification systems and perform pre-shipment audits based on each retailer's exact requirements. Our warehouse systems validate label placement, barcode formats, pallet specs, and more.

Yes. Our facilities are designed to handle multi-channel workflows, allowing us to pick-pack and label D2C orders while simultaneously preparing retail-compliant cases and pallets.

We meet GS1-128 barcode standards, retailer-specific palletization, shelf-ready displays, and WHMIS-compliant packaging. We also accommodate special handling instructions for fragile, perishable, or hazardous items.

Our onboarding process typically takes 10-14 days. It includes alignment on SKU specs, retailer requirements, test orders, and workflow setup to ensure accuracy from day one.